Sterile Processing

Latest News

The tool uses nodes, lettered A to O, that assess products in a way that spans labeling, marketing, and regulatory data, says the CDC. It provides a rigorous standardized method for review.

Although all patients require vigilant infection prevention measures and the goal should always be zero infections, the stakes are sometimes higher in the NICU, as infections there have higher potential for death.

Several manufacturers that are falsely marketing ozone gas or UV light-based products claiming to clean, disinfect or sanitize CPAP devices and accessories.

The agency has been pushing to make the LivaNova Heater-Cooler System 3T safer since 2015.

About 20% of passengers in an airport have clean hands. If that increases to 30%, a potential infectious disease would have a worldwide impact that is about 24% smaller.

Seqirus announced today that the US Food and Drug Administration (FDA) has approved Fluad Quadrivalent, touted as the first and only adjuvanted quadrivalent influenza vaccine, developed to help protect adults 65 years and older against seasonal influenza.

It is in the best interest of the patient that the system moves to either disposable components or scopes, as duodenoscopes have shown a propensity for disease transmission.

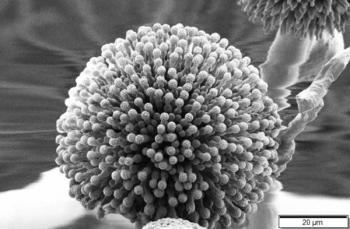

The Aspergillus mold was detected in the hospital’s operating rooms on Nov. 10, shortly after 6-month-old Elizabeth Hutt underwent her third heart operation.

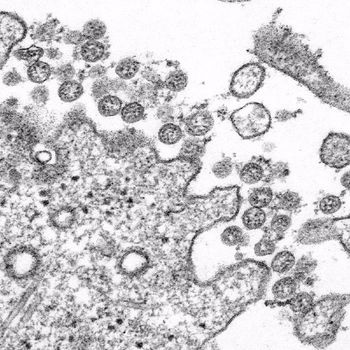

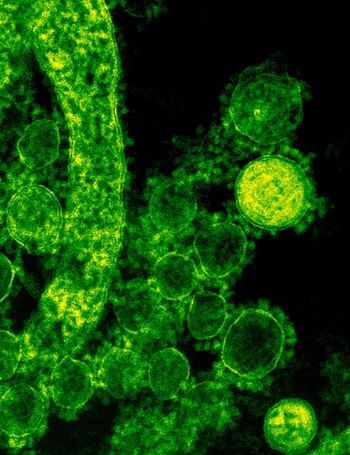

It's been given an official name, COVID-19, and will likely become known as SARS-CoV-2, when all is said and done.

Latest development in the push to reduce risk of infection from the devices.

The company is trying to find ways to keep the move from affecting patients and providers.

"Infection preventionists are frontline workers who are in an excellent position to intercept unnecessary antibiotic usage."

Outbreaks in NICUs are particularly challenging in that not only are the patients vulnerable to infections, but often the design and layout of these units (often a pin-wheel configuration) coupled with family visits bring about inherent challenges.

Disposable designs will improve patient safety

How do we clean an instrument has always been the question of the day in sterile processing departments all over the world; the answer is to come. The sad truth is, in some instances, the cleaning process was derived from someone in leadership making up a rule.

When it comes to the culture of a hospital, nothing is as important as the employees who work for it and aim to provide excellent patient care. When it comes to a hospital's balance sheet, particularly the physical assets, nothing is as important as the actual hospital and other ancillary buildings.

There are many misconceptions about using ISOs for endoscope repair. Perhaps the one with wide-ranging implications is the misconception that using an ISO for service will invalidate the device’s 510K, instructions for use (IFU), or automated endoscope reprocessor (AER) validation.